The Future in Layers: How 3D Printers Are Changing Everything

3D printing, also known as additive manufacturing, has revolutionised the way things are made across various industries. From aerospace to healthcare, 3D printers are at the forefront of innovation, creating new possibilities and pushing boundaries. As this cutting-edge technology continues to evolve, the future of printing is taking shape in layers – quite literally.

How 3D Printing Works

3D printers work by building objects layer by layer, using materials such as plastics, metals, and ceramics. This layer-by-layer approach allows for complex geometries and intricate designs that were once impossible to achieve with traditional manufacturing methods. The versatility and precision of 3D printers have made them indispensable in fields like engineering, architecture, and even fashion.

Industrial Applications and Business Benefits

Industrial 3D printing has been a game-changer for many businesses, enabling:

-

Rapid prototyping

-

Customised manufacturing

-

On-demand production

Companies can now produce parts and components with high levels of complexity and at a fraction of the time and cost compared to traditional methods. This has led to increased efficiency, reduced waste, and enhanced product quality.

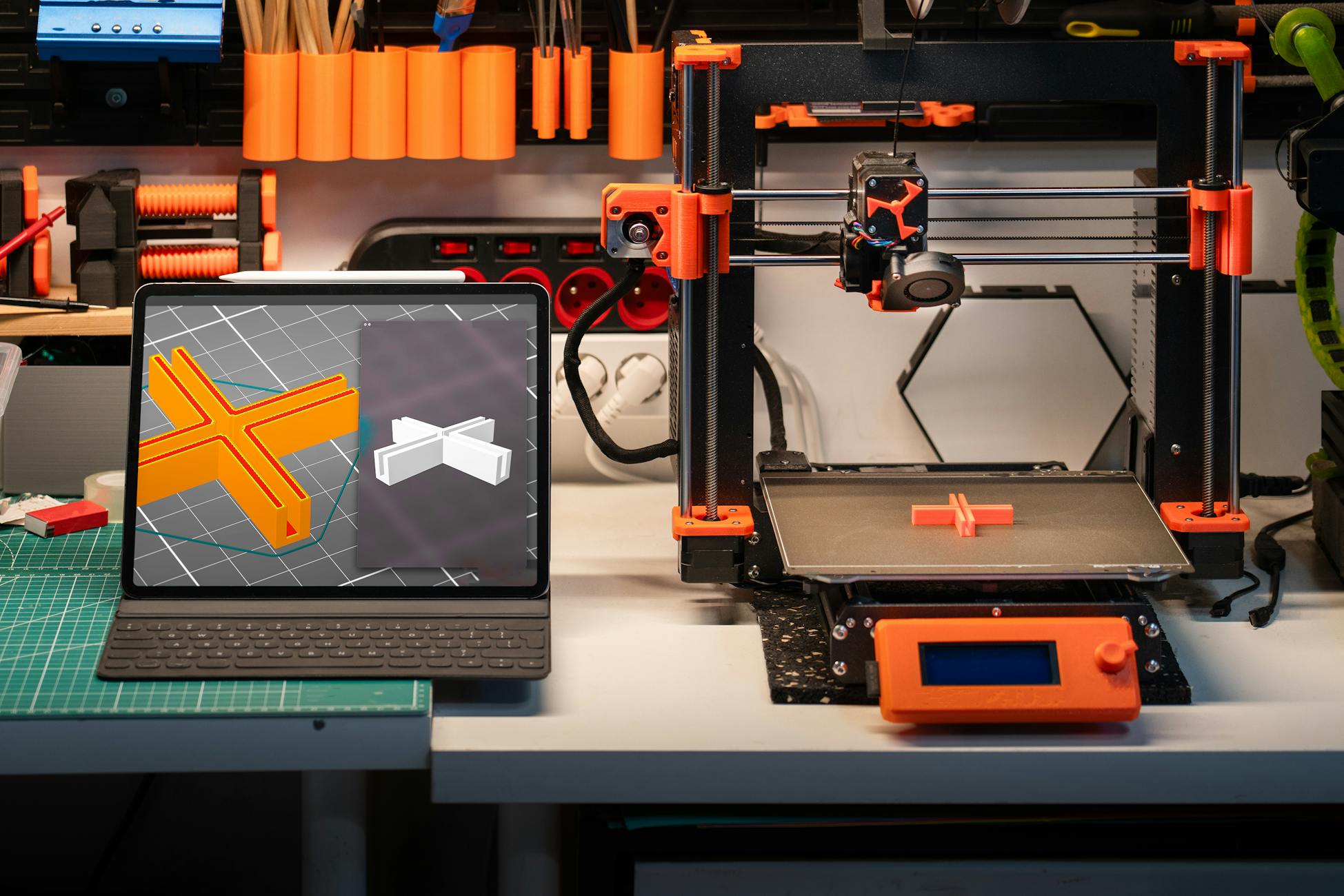

3D Printing at Home

But it's not just in the industrial sector where 3D printing is making waves. The rise of home 3D printers has brought this technology into the hands of consumers, hobbyists, and educators. With a home 3D printer, anyone can unleash their creativity and bring their ideas to life. From personalised gifts to DIY projects, the possibilities are endless.

Evolving Technology and New Frontiers

One of the key trends in 3D printing is the continuous improvement of 3D printer technology. Manufacturers are constantly pushing the boundaries of:

-

Speed

-

Accuracy

-

Material options

This ongoing innovation has paved the way for new applications in industries such as healthcare, where 3D printing is used to create:

-

Patient-specific implants

-

Prosthetics

-

Even human tissue

Sustainability and Supply Chain Transformation

The benefits of 3D printing extend far beyond manufacturing. By enabling decentralised production, 3D printers have the potential to revolutionise supply chains and logistics.

Localised production:

-

Reduces the need for large warehouses

-

Minimises long-distance shipping

-

Saves time, money, and resources

This shift towards on-demand manufacturing is more sustainable and responsive to market demands.

What the Future Holds

As 3D printing technology continues to advance, we can expect even more exciting developments:

-

Creation of smart materials

-

Integration with robotics and artificial intelligence

3D printers are not just changing how things are made – they are reshaping the way we think about design, production, and innovation.

Industry-Wide Adoption

With the increasing accessibility of 3D printing technology, more industries are embracing additive manufacturing as a viable production solution.

From:

-

The automotive sector

-

To the food industry

…businesses are exploring how 3D printers can streamline processes, reduce costs, and drive innovation.

Speed, Agility & Customisation

One of the key advantages of 3D printing is the ability to create custom designs and prototypes quickly and cost-effectively.

This flexibility allows:

-

Rapid iterations

-

Faster time-to-market

-

Greater design precision

In today's competitive economy, speed and agility are critical — and 3D printers deliver both.

Sustainability Benefits

Another area where 3D printing is making an impact is sustainability.

Unlike traditional manufacturing, which often produces large amounts of waste, additive manufacturing:

-

Uses only the material needed

-

Minimises environmental footprint

-

Encourages eco-friendly production

Hybrid Manufacturing and Integration

As the technology matures, 3D printing is being integrated into existing production workflows.

Hybrid manufacturing systems, which combine additive and subtractive processes, are emerging to:

-

Leverage the strengths of both approaches

-

Create complex, high-precision parts

-

Increase manufacturing flexibility

Conclusion: A Multi-Layered Future

In conclusion, 3D printing is not just a passing trend – it is a transformative technology reshaping industries and fuelling innovation.

The future of printing is:

-

Multi-layered

-

Dynamic

-

Full of potential

As we continue unlocking the capabilities of 3D printers and exploring new applications, the possibilities are truly limitless.

From personalised products to sustainable solutions, additive manufacturing is changing everything – one layer at a time.